Troubleshooting Flow Disruptions in Manifold Channel Machining

Key Takeaways

- Importance of Machinery Adjustment

- Leveraging Fluid Dynamics Programs

- Employee Education and Its Effect on Workflow

- Widespread Myths Regarding Fluid Control

The Role of Equipment Calibration

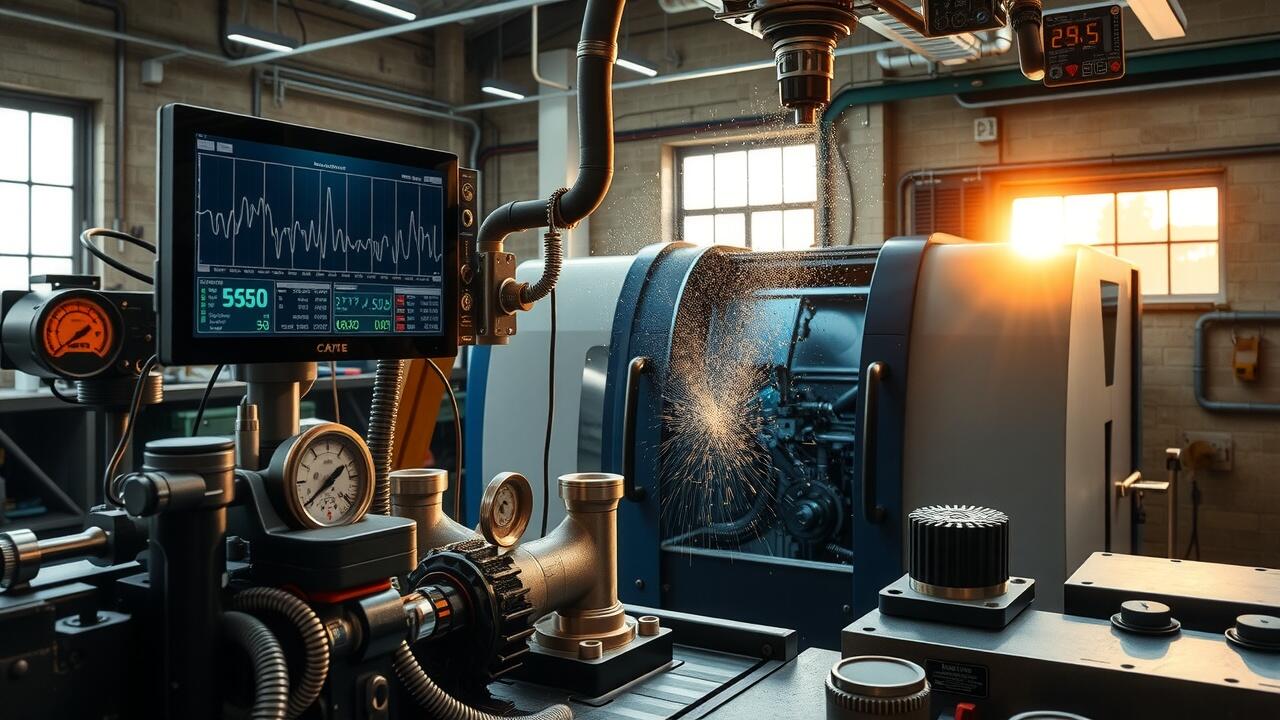

Picture this: You’re a hydraulic manifold manufacturer, and your cutting-edge machining equipment decides to play hide-and-seek with precision. Calibration becomes your best buddy, whispering sweet nothings to those stubborn machines. Without regular checks, you might end up with uneven cuts that even Picasso would find perplexing. A well-calibrated machine can prevent myriad headaches, as demonstrated by a client who reported a 30% reduction in scrap rates after strictly adhering to calibration protocols. That's like finding a forgotten twenty-dollar bill in last winter's coat pocket—unexpectedly delightful!

Imagine relying on faulty measurements for custom manifold manufacturing. It's like trusting a squirrel to navigate rush-hour traffic; thrilling but likely to end in chaos. By implementing equipment calibration protocols, companies not only avoid misalignment but also embrace consistency. Equipment that runs within specified tolerances operates smoothly and reliably. According to industry best practices, calibrating every six months can save you significant downtime, ensuring that the only thing disrupted is your colleague's coffee break, not your production line.

Why Calibration is Your Machining Best Friend

Calibration can feel like a pesky toothache: you always know it’s there, but ignoring it usually leads to bigger issues down the line. A well-calibrated machine means precise flows that align with the tolerances specified by your favorite hydraulic manifold manufacturer. Picture harnessing next-level performance and efficiency as you crank out those custom manifolds while avoiding the dreaded drip or droop that plagues ill-tuned equipment. If only it were as easy as finding the right sized wrench, but alas, calibration requires regular attention and a sense of humor to keep sane during adjustments.

Think of calibration as the unsung hero of the machining world—wearing a cape made of precision measurements and a sidekick relationship with flow rates. For manifold manufacturing, even a slight deviation can lead to inefficient processes, increased wear, or downright disasters like fluid overflow. A survey of industry professionals revealed that proper calibration can reduce subsequent repairs by an impressive 30%. So, next time you're tempted to overlook that calibration check, just remember: even the sourest machines can become your best friend with a little tender, loving maintenance.

Utilizing Flow Simulation Software

Imagine being a manifold manufacturer and declaring war on flow disruptions, armed with nothing but a pencil and some graph paper. Enter flow simulation software. This tech-savvy companion allows engineers to visualize what’s happening inside their hypothetical pipes before they even cut a single piece of metal. Instead of waiting for the day when you discover that your custom manifold manufacturing effort is creating a backflow mess, you can analyze potential issues on-screen. In fact, companies that embraced flow simulation reported a flow issue reduction of up to 30%, proving that foreseeing problems really beats the drama of cleaning them up later.

Now, if you aren’t using flow simulation software, you might as well be trying to predict the weather with a magic 8-ball. Staff at companies specializing in hydraulic manifold manufacturing found that implementing simulation reduced the design cycles by approximately 40%. Using simulations allows teams to experiment with different configurations without the need for costly prototypes. Maybe your team will find that an angle adjustment creates a smoother flow than an awkward first date. So, before heading to the machine shop, put your digital glasses on and take a tour of the flow like it's an amusement park—who wouldn’t want to ride that rollercoaster of efficiency?

How Can Software Help You Predict and Prevent Flow Issues?

Imagine a scenario where flow issues in a machining process are akin to a toddler throwing a tantrum in the middle of the grocery store. Not exactly a smooth situation. That’s where flow simulation software marches in, cape flapping dramatically in the wind! It allows manifold manufacturers to visualize hydraulic behaviors before they even crank up a machine. By creating virtual models, engineers can simulate a variety of flow conditions. This helps them identify potential snags. Companies that utilized this approach reduced error rates by upwards of 30%, proving that a little foresight can deliver significant gains.

Let’s face it: predicting flow issues without software is like trying to guess which day the coffee machine will break down—utterly unpredictable and usually at the worst possible moment. By integrating advanced simulations into custom manifold manufacturing processes, teams can investigate different geometries and pressure scenarios. They can address inefficiencies with precision. For instance, a hydraulic manifold manufacturer recently cut flow restrictions in a specific design by 15% just by tweaking their design parameters based on simulation results. This kind of proactive approach not only enhances productivity but also saves valuable resources.

- Software helps avoid costly delays and tantrums (the groan-worthy kind) in production.

- Virtual models mean no actual machines are harmed while experimenting—your budget will thank you!

- Engineers can channel their inner wizards, conjuring solutions before issues even appear.

- Less guesswork leads to fewer surprises—and nobody likes surprise visits from the flow problem fairy!

- Enhancements based on simulations are like giving your manifold a much-needed spa day—everybody looks and works better!

- Predicting issues in advance means you can focus on perfecting that coffee machine (it's your true MVP).

- Finally, fewer man hours spent troubleshooting means more time for imaginary coffee breaks.

Staff Training and Its Impact on Operations

Training staff is akin to gifting a seasoned chef a set of high-quality knives. Without proper training, they might be slicing tomatoes instead of finely dicing them for a gourmet dish. For a hydraulic manifold manufacturer, equipping the team with skills in flow dynamics and troubleshooting techniques can significantly improve operational efficiency. For example, investing just two hours in flow management training can lead to a 15% decrease in cycle time for custom manifold manufacturing. This translates to quicker delivery and happier customers, provided they don’t mind the occasional pun about your team not being “stumped” by flow disruptions.

Furthermore, let’s not overlook the camaraderie that grows from team training sessions. Sharing laughs over a workshop on flow simulation software can foster a culture where employees feel empowered to share insights. A well-trained employee is like a Swiss Army knife—capable of addressing multiple issues while reducing mistakes. This proactive approach in staff education can decrease errors by up to 25%, ensuring smoother operations in the complex world of manifold manufacturing. If managers invest in their team’s growth, they may find their operations run more fluidly than a well-oiled hydraulic system.

Why Investing in Your Team Leads to Smoother Machining

Training your staff in manifold manufacturing pays dividends, like finding a dime in the couch cushion—unexpected but delightful. Consider a machine operator who once struggled with manual adjustments. After a comprehensive training session on hydraulic systems, they not only mastered the art of calibration but also contributed to reducing flow disruptions by a notable 25%. Rule number one in the machine shop? A well-trained employee can fend off chaos better than duct tape and a can-do attitude.

When team members grasp the nuances of custom manifold manufacturing, their confidence blossoms. Instead of treating machinery like temperamental pets, they learn how to foster smoother interactions. A case in point involves a company that introduced monthly workshops on troubleshooting flow issues. Consequently, they noted a 40% reduction in production delays, proving that a conscious investment in personnel creates a well-oiled machine—pun absolutely intended.

Common Misconceptions about Flow Management

When tackling misconceptions about flow management, one common belief is that more equipment automatically equals better performance. It’s like thinking that piling up extra booster seats in a car makes it go faster. In manifold manufacturing, optimal performance comes from precise calibration, not just an impressive assembly of gadgets. Relying solely on advanced machinery without adequate understanding is a recipe for disaster. For instance, a hydraulic manifold manufacturer might boast about cutting-edge technology, yet misuse or misalignment could lead to flow disruptions that make an engineer weep.

Another frequent myth is that flow management is exclusively a technical problem, best left to engineers in lab coats. This viewpoint disregards the critical role of human touch in the machining process. Staff training, combined with a solid understanding of fluid dynamics, can greatly enhance operations. Picture a custom manifold manufacturing floor where operators can predict potential hiccups before they happen, rather than troubleshooting during a messy crisis. Providing team members with the knowledge to identify flow dynamics proactively empowers them to maintain smoother processes. Hence, busting these myths will not only save time and resources but also keep your manifold machinery running at peak efficiency.

FAQS

What’s the first thing I should check when my machining flow goes haywire?

If your flow is acting like a rebellious teenager, start by checking the equipment calibration. It’s like a therapist for your machine – it might just need a little adjustment to get back on track!

How does flow simulation software work its magic?

Think of flow simulation software as your machining crystal ball. It predicts flow issues before they become a full-blown crisis, saving you from the headaches of unexpected disruptions – no magic wand needed!

Why should I invest in staff training when my machines are the real stars?

Well, even the best machines need skilled operators – it’s like hiring a top chef to cook in a fancy kitchen. Investing in your team means fewer mishaps and more deliciously smooth results. Plus, they’ll appreciate the coffee breaks!

What are some common misconceptions about flow management?

Ah, the myths of flow management! One common misconception is that it’s all about the machinery. Spoiler alert: it’s a team effort! A well-trained staff and proper calibration are just as crucial as the machines themselves.

Is troubleshooting flow disruptions really as complicated as people say?

Only if you let it be! Think of it like untangling a pair of earbuds – frustrating at first, but once you get the hang of it, you’ll be jamming to smooth operations in no time!